25 Mar 2022

Scientific research on oxygen therapy and oxygen health care has received worldwide attention. With the development of China's aging population, as a tool for home health care and oxygen therapy, the household oxygen concentrator will become one of the household appliances serving the health care and rehabilitation of the elderly.

From the current situation, product technology and standards of the household oxygen concentrator industry, the working principle and technical requirements of the household oxygen concentrator are analyzed, the development direction of the household oxygen concentrator is predicted, and the implementation of the industry standard "Household oxygen concentrator" is pointed out. It provides useful help for industry practitioners and consumers to choose and buy.

Important of oxygen

Oxygen is essential for human survival and health, it is related to the new and old of the human body process. The medical profession calls 30% oxygen "rich oxygen", also known as "life oxygen".Under this oxygen concentration environment, physical function, brain intelligence, and blood oxygen concentration all reach the highest level of the human body.In good condition. Oxygen health care originated in Western Europe and is regarded as a method of advanced fitness.

Since the 1980s, Mexico, the United States, and Japan have successively carried out oxygen health care. In economic development countries more than 20% of the households have small oxygen-generating equipment for their families to carry out oxygen protection healthy. The emergence of oxygen therapy and oxygen health care means that people's demand for oxygen is completely dependent on the transition of nature to further independent struggle has opened up a new way of supply and demand for oxygen and human beings.

The development of household oxygen concentrator industry

In recent years, with the improvement of people's living standards, the deepening of the concept of health, and the arrival of an aging society, the demand for household oxygen has been increasing, which has led to the rapid development of the household oxygen concentrator industry and has gradually become one of the emerging household appliances.

The birth of the household oxygen concentrator has changed the status quo that only medical oxygen concentrators are available in the world, provided the possibility for miniaturized non-medical oxygen concentrators to enter ordinary consumer families, and greatly promoted the the coverage of oxygen health care in the world.

Working principle of the household oxygen concentrator

Molecular sieve oxygen concentrator was successfully developed by the United States in 1960, industrialized in 1970, and quickly widely used in the world. The demand ratio of oxygen concentrators for respiratory products in the US market is 37%. In aggregate, demand outside the United States is only approximately equal to that in the United States. Since the 1970s, molecular sieve oxygen concentrators have developed rapidly, and in recent years, the development momentum has become more vigorous. At present, the main producers of molecular sieve oxygen concentrators are the United States, Germany, the United Kingdom, Canada, South Korea and Japan.

According to WHO statistics, the global respiratory medical expenditure is about 480 billion US dollars, and respiratory products account for 32%, and the market demand increases by about 11% every year. With each the strengthening of the national government's health care policy and the deterioration of ambient air quality, resulting in an increase in respiratory infectious diseases, coupled with the aging of the global population and other reasons, will have a profound impact on the growth of the oxygen concentrator market.

With the increase of the elderly population in the world, geriatric diseases have become a problem that plagues society and families. Due to the fact that oxygen concentrator equipment for health care has just started, the current household ownership rate is less than 1%. Medical literature shows that oxygen inhalation has a good effect on relieving and preventing cardiovascular and cerebrovascular diseases and respiratory system diseases in the elderly.

Oxygen therapy and oxygen health care can promote the physical and mental health of the human body, make people energetic, and enhance people's ability to withstand tension and pressure; especially for improving the disease resistance of middle-aged and elderly people, reducing symptoms, accelerating recovery and avoiding sequelae. Therefore, as a product suitable for family use, improving the quality of life of middle-aged and elderly people and promoting health, the home oxygen concentrator has a very broad development prospect.

The oxygen production methods of the oxygen concentrator

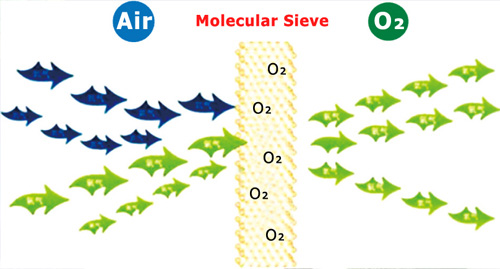

At present, household oxygen concentrators mainly have two types of oxygen production methods: pressure swing adsorption and membrane separation. Among them, the pressure swing adsorption method for oxygen production is also called molecular sieve oxygen production. Pressure swing adsorption method: Gas separation is carried out by using molecular sieves with different adsorption and release capabilities of specific gases. The magnitude of adsorption and release of a single gas decreases with different pressure changes low or increased, for example, under high pressure, the adsorption capacity of molecular sieve for a single gas increases; under low pressure, the amount of released gas increases. The molecular sieve obtains the corresponding gas through repeated adsorption and release of the gas. The pressure swing adsorption method has the advantages of low energy consumption and low cost.

Membrane separation method: The semi-permeable membrane is used to separate oxygen and nitrogen in the air. Under different pressures, the ability of oxygen and nitrogen to pass through the semi-permeable membrane is different. The higher the pressure, the faster the oxygen permeates through the membrane. The membrane separation method has the advantages of low cost and simple process, but the disadvantage is that it requires high performance of the permeable membrane, and the concentration of oxygen produced is extremely dependent on the permeation performance of the membrane. The initial value of the oxygen concentration produced by the pressure swing adsorption type household oxygen concentrator can reach more than 93%, and the initial value of the oxygen concentration produced by the membrane separation type household oxygen concentrator is usually about 30%. This paper takes the pressure swing adsorption oxygen concentrator as an example to introduce the working principle of the oxygen concentrator.

The product structure of the oxygen concentrator

The product structure of the oxygen concentrator mainly includes: intake air filter device, intake air muffler device, air compressor, heat dissipation cooling device, molecular sieve oxygen generation system (adsorption tower), solenoid valve, control circuit and flow meter. Oxygen making system, compressor and control panel are the three main components of the oxygen making machine. Among them, the oxygen generation system has the most complex process and is also the core component of the oxygen concentrator. It integrates the integrated combination of various processes such as pneumatic principle mechanism, pipeline air pressure coordination system, mechanical structure pressure components, material application, and sealing structure. The gas circuit structure of the oxygen system of the oxygen production mechanism.

1. Filter

2. Oil-Free Air Compressor

3. Solenoid valve

4. One-way Valve

5. Molecular Sieve Tower

6. Balance valve

7. One-way Valve

8. Solenoid regulator valve

9. Muffler

The figure above shows the gas circuit structure of the oxygen system of the oxygen production mechanism. The working principle of the oxygen concentrator is to use the molecular sieve pressure swing physical adsorption and pressure swing desorption technology. Through the embedded molecular sieve, when pressurized, nitrogen in the air can be adsorbed, and the unabsorbed oxygen can be collected. After purification that is change to high-purity oxygen. When the pressure reaches a certain height, the decompression begins, and the molecular sieve discharges the adsorbed nitrogen back into the ambient air. In the next pressurization, oxygen can be produced by adsorbing nitrogen, and the whole process is a periodic dynamic cycle process.

At present, all medical oxygen concentrators use PSA pressure swing adsorption and air separation oxygen production technology. When the air enters the bed room with the adsorbent, the nitrogen has a strong adsorption capacity and is adsorbed, but the oxygen is not adsorbed, so that a high concentration of oxygen can be obtained at the outlet end of the adsorption bed. Since the adsorption capacity of the adsorbent has the characteristic of changing with the pressure, changing its pressure can make the adsorption alternate.

The specific working process of the household pressure swing adsorption oxygen concentrator is to compress the air first. After being purified by the air purification dryer, it enters the adsorption tower through the switching valve. In the adsorption tower, the nitrogen is adsorbed by the molecular sieve, and the oxygen is collected at the top of the adsorption tower. After entering the oxygen storage tank, clean oxygen can be obtained after being filtered by deodorization, dust removal filter and sterilization filter.

Keywords: oxygen concentrator

Originally published 25 Mar 2022, updated 25 Mar 2022.