12 Aug 2022

Medical oxygen concentrator is an indispensable equipment for hospitals to carry out medical work. Understanding its operation principle, correct use and maintenance is the key to ensure its safe and stable operation. The medical oxygen concentrator needs to go through the following modules to generate medical oxygen, that is, first through the air compressor system, air storage tank and oxygen production system, and finally through the oxygen storage tank. Combined with the operation principle of the medical oxygen concentrator related system, the common faults are analyzed, and some correct use and maintenance methods are proposed.

Principle of Medical Oxygen Concentrator

PSA (pressure swing adsorption) technology is the key technology used by medical oxygen concentrator, which can extract oxygen from the air. Molecular sieves are filled in medical oxygen concentrator. Usually, the surface area of molecular sieves can reach 800~1000m2/g. Using molecular sieve flow adsorption technology and analytical technology, hydrogen in the air can be adsorbed under pressure without being adsorbed. The oxygen collected in the air will be collected in a concentrated manner, and then the purification treatment function will be used to process the oxygen collected in the air into high-purity oxygen. The previously adsorbed ammonia gas is re-emitted to the air under reduced pressure. Then chlorine gas can be adsorbed, and under pressure again, it can be used for the production of oxygen.

The medical oxygen concentrator can perform periodic cycle oxygen production, and its oxygen production process is a continuous and constantly changing process. Purification of compressed air can be done by air purification desiccant, and finally the air enters the adsorption tower by switching the door. Molecular sieves will adsorb chlorine gas, and in the adsorption tower, oxygen will gather again, and finally be pushed into the oxygen and gas storage tank. The concentration can reach 96%. And the whole preparation process does not involve any chemical principle, so it will not cause any pollution to the environment.

Common faults and maintenance methods of medical oxygen concentrators

1. Molecular sieve failure

There are various moving parts of the oxygen concentrator, including diaphragms, various valves, valve cores, etc. If continuous operation for a long time, the diaphragm will rupture, and the top of the valve core will be easily deformed, which will eventually lead to the difficulty of closing the electromagnetic reader normally, which will affect the analysis and adsorption of molecular sieves. effect, and then affect the operation effect of the entire oxygen concentrator. Molecular sieve is a very important component and plays an important role in the entire oxygen production process. However, due to various reasons, there will be problems of oil ingress or moisture, loss of normal functions, and shortened service life. Therefore, it is very necessary to do regular maintenance and replacement of molecular sieves.

2.Air compressor failure

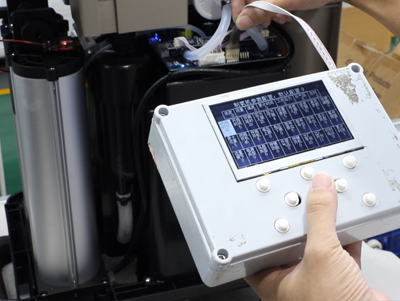

(1)The air compressor of the oxygen concentrator consists of 2 screw air compressors, which are controlled by a microcomputer, and the pressure is usually set to 6~8kg/cm2, because the operation and composition are more complicated, and it is also the part that is most prone to failure. The common faults and maintenance methods of air compressors are as follows.

The pressure value of the air compressor never reaches the upper limit of 0.74 MPa, and it is always in the loading state, with a lower air tank pressure. For this fault, first check the oxygen concentrator, if the oxygen concentrator is turned off, the fault is eliminated, and the pressure of the air tank rises, indicating that the compressor air is sufficient, then the oxygen concentrator is eliminated, and the fault is eliminated; replace the air filter at the air inlet, if the fault persists , then the filter element failure is eliminated; finally, the compressor is checked off-line, and it is found that the air inlet is not fully opened, the solenoid valve does not fully act, and the air circuit is not completely closed, causing the connecting rod of the suction regulating valve to not move to the end, clean the solenoid valve, and restart the The fault is cleared after startup.

(2)The loading state of the air compressor can be loaded to the upper limit, but the phenomenon of deflation occurs. In response to this problem, first check the electromagnetic, if there is air leakage, then further check the internal sealing ring, if there is damage, replace the old one with a new one in time. Although the fault is not very serious and will not affect the normal operation of the compressor, long-term loading will further increase the overall loss of the air compressor system.

(3)The temperature of the air compressor exceeds the standard limit, that is, >90°C. For this fault, firstly check whether there is oil leakage in the compressor, and check whether the oil pipe is broken. If these problems occur, the oil pipe should be replaced in time; if these problems do not appear, check the oil pipe filter and oil cooler. If the oil contamination of the oil cooler is too serious , to be cleaned up in time.

In addition, if it is summer, the door on one side of the compressor should be opened regularly, and the temperature will drop, which will help prolong the use of the oil pipe. The maintenance of the air compressor can further reduce the failure rate and prolong the service life of the equipment. (1) Regularly replace the air filter element and oil filter element; (2) Regularly check whether the pipeline and air path are blocked or damaged; (3) Regularly check and replace the solenoid valve components that are easy to age 10); (4) Regularly Observe the abnormal operation of the machine.

3. The medical oxygen concentrator cannot be started normally

The reasons and maintenance of the medical oxygen concentrator not starting normally are as follows. (1) When the outlet pressure of the air machine is higher than 0.5 MPa, the hand valve under the air can be opened at this time to reduce the air pressure of the pipeline. (2) If the central control screen is not reset, there are three ways to deal with it: you can directly click the "reset" button on the screen; if the problem is the pressure sensor, you can directly replace it with a new one; in addition, the temperature is too high or too low It is also easy to cause the oxygen concentrator to fail to start. If it works at a temperature lower than 0℃ or higher than 40℃ for a long time, the failure rate will be higher. You should adjust the indoor temperature in time. If it is used in outdoor cold air Insulation measures should be taken. If the above reasons are eliminated, it is considered to be a battery problem, and the gas supply can be switched to the busbar, and then the main power supply can be detected.

Optimize the management of oxygen production equipment

In addition to the correct use of hospital oxygen equipment and the maintenance and maintenance work, we should continue to optimize and improve the existing use system specifications to make the use and use of oxygen equipment more standardized and standard.

(1)Refurbish the existing specifications for the use of oxygen-generating equipment, optimize and formulate work systems and workflows based on common faults and problems that often occur during use, and further play the role of constraints, management, and supervision. Reasonably divide the responsibilities of the staff of relevant departments, and carry out daily supervision and assessment.

(2)To establish safety awareness, it is necessary to ensure that oxygen-generating equipment and equipment are kept away from flammable and explosive and other dangerous items, no fireworks, no oil, no leakage, and emergency measures are formulated. In case of emergencies, such as fire, explosion, etc., The main power supply should be cut off immediately, the oxygen general reading should be turned off in time, and the report should be reported to the superior immediately. In case of a large-scale and long-term power failure, the oxygen busbar should be opened in time, and the standby unit should be switched to try to repair it.

(3)(3)Sufficient spare parts should be provided, including air filter, oil filter, oil and gas separator filter, etc. If the oxygen concentrator is used for more than 1000 hours, a set of key electromagnetic reading diaphragm components should also be reserved to deal with sudden failures.

Summarize

Medical oxygen concentrator is a very important equipment component in medical rescue work. It can be used to produce high-purity oxygen. However, because of its complex internal composition, many system devices and parts are involved, and improper use and maintenance are prone to various failures. Therefore, it is necessary to do a good job in the daily maintenance and maintenance of the medical oxygen concentrator, timely screening potential hidden dangers, take a scientific and reasonable method to solve the fault, and constantly establish and improve the relevant management system, really ensure the stable, continuous and safe work of the medical oxygen concentrator.

Keywords: oxygen concentrator

Originally published 12 Aug 2022, updated 12 Aug 2022.