28 Dec 2021

Medical research has shown that most people are often in a state of hypoxia due to environmental pollution and the pace of life is accelerating. Oxygen is an important element in human body. Nutrients must be oxidized to produce and release energy. At the same time, it is necessary that the participation of oxygen in the human body’s metabolism process. Oxygen therapy with oxygen concentrator is an important treatment method in medicine. Insist on oxygen therapy, it is plays a significant role in the complete recovery of human body.

The principle of molecular sieve pressure swing adsorption

In the oxygen therapy of terminal individuals, the conventional oxygen supply devices mainly include oxygen bags and small oxygen cylinders. This type of device requires oxygenation continuously, not only the oxygen capacity is limited, but also inconvenient to use. So that it can’t guarantee long-term oxygen supply.

Considering that the molecular sieve pressure swing adsorption (PSA) method of the oxygen concentrator production not only has a high concentration, but also does not produce harmful gases, so this article mainly introduces this physical method.

PSA is mainly composed of air purification system, oxygen and nitrogen separation system, oxygen buffer, detection system, etc.

The basic working process is: The compressed air output by the air compressor in the oxygen concentrator is cooled and the water vapor in the air changes from gas to liquid. Filtered by the water separator then activated carbon filter gets dry compressed air after degreasing, and then dry compressed air Enter the oxygen-nitrogen separation system, which the polar nitrogen molecules are preferentially adsorbed by the zeolite molecular sieve, and the oxygen molecules are output into the buffer tank through the system valve, then the flow detection unit combined with the oxygen purity to control the oxygen output finally.

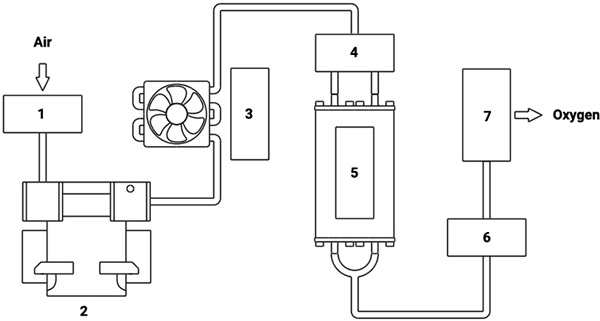

Schematic of Oxygen Concentrator

1. Filter

2. Oil-Free Air Compressor

3. Cooling System

4. Separating Valve

5. Molecular Sieve Tower

6. Control Valve

7. Humidifying Water Tank

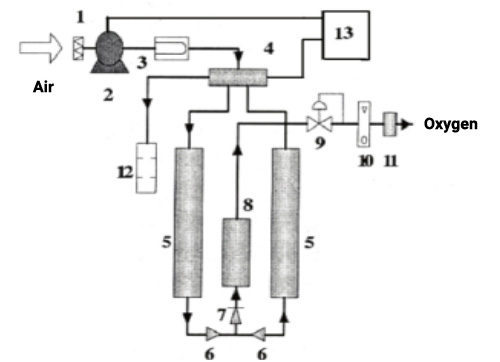

Pressure swing adsorption oxygen concentrator structure

It is shown in the figure below the process flow of the pressure swing adsorption oxygen concentrator. The filtered air enters the compressor in the oxygen concentrator. The compressed high-pressure air enters the adsorption tower for adsorption and separation after cooling. Part of the separated oxygen enters the gas storage through the one-way valve. The tank is decompressed by a pressure reducing valve and then flows out through a flow meter and a humidifying bottle for users to use.

The other part of oxygen is used for backflush cleaning of the adsorber in the desorption state, and the desorbed nitrogen is discharged through the muffler.

According to the different functions of the various components in the oxygen production process, the PSA oxygen concentrator can be divided into functional modules such as air source system, separation system, desorption system, control system, and product system.

Otherwise, the gas source system provides clean, high-pressure non-high-temperature gas for the oxygen process of the oxygen concentrator, the separation system realizes the adsorption and separation of oxygen and nitrogen, then the desorption system realizes the discharge of exhaust gas and the cleaning and desorption of the adsorbent bed.The control system ensures the normal and efficient operation of the oxygen production system.

The oxygen concentrator system ensures that the oxygen is output stably at a certain pressure and flow rate, to humidify the oxygen to suit the user's breathing.

1. Filter

2. Compressor

3. Cooler

4. Solenoid valve

5. Adsorber

6. Backflush valve

7. One-way valve

8. Air tank

9. Pressure reducing valve

10. Flowmeter

11. Humidifier bottle

12. Muffler

13. Control panel

Features of PSA oxygen concentrator

The PSA oxygen concentrator takes oxygen at room temperature and low pressure. The equipment has the advantages of simple process flow, low investment, low energy consumption, safe and reliable use, simple operation, and easy maintenance and repair.

Due to its simple equipment and small size, it can be used to produce oxygen with conventional electricity. It is suitable for producing oxygen on-site in medical units where oxygen is indispensable but the demand is not particularly large.

In addition, the PSA oxygen concentrator process has technical advantages such as compact equipment, low investment, and high degree of automation.

Quality control of oxygen concentrator

According to the functional characteristics of the oxygen concentrator, the quality of a device can be objectively expressed through the three parameters of pressure, flow rate, and oxygen concentration. As long as one of them has changed significantly, it will affect the working state of the oxygen concentrator.

Therefore, these three parameters are usually highly sensitive parameters are used as indicators to detect the performance of the oxygen concentrator. The oxygen flow rate is an important parameter of the oxygen concentrator. It reflects the oxygen system capacity of the oxygen concentrator. At present, the maximum output flow of most oxygen concentrators is 5L /min, individual models can reach 6 L/min.

In the same unit time, the more end oxygen produced, the better the quality of the oxygen concentrator.But on the other hand, when the oxygen flow rate is increased, it is need to attention the issue that whether the oxygen concentration requirement can be guaranteed.

It is fixed the amount of molecular sieve loaded in the adsorption tower. In the same time, the less the amount of oxygen, the greater the difference between the amount of feed gas entering the adsorption tower and the amount of product gas flowing out of the adsorption tower, the faster the pressure in the adsorption tower rises. It is very beneficial to increase the adsorption capacity of the molecular sieve in the adsorption tower.

In addition, because of the high pressure in the adsorption tower, larger pressure difference between the inside of the adsorption tower and the outside, which is very beneficial for the complete desorption of the adsorbed components in the adsorption tower. Therefore, the smaller the oxygen flow, the higher the corresponding oxygen purity.

It is easier to find the trend and tendency problems of key parameters through detection, determine the measures and timing of preventive maintenance and repair in time, and carry out preventive maintenance or maintenance at the right time, which will greatly reduce the occurrence of failures and effectively improve the safety factor of patient oxygen concentrator use. The quality inspection of oxygen concentrator belongs to the category of people's livelihood measurement.

Keywords: oxygen concentrator

Originally published 28 Dec 2021, updated 28 Dec 2021.