02 Dec 2022

Oxygen therapy is mostly used to correct hypoxia, improve tissue hypoxia, promote metabolism, and maintain the body's vital activities, and the oxygen concentrator is one of the important medical tools to assist in the treatment of many diseases.

There are three main clinical oxygen supply methods, cylinder manifold oxygen supply, liquid oxygen storage tank oxygen supply and medical molecular sieve oxygen machine oxygen supply.The gas source for the first two types of oxygen supply is produced using low temperature air separation. Medical molecular sieve oxygen concentrator oxygen production technology is a gas separation and purification technology developed in the past 40 years.It is mostly used for local oxygen production in medical units where oxygen is indispensable and not particularly needed, and solves the problem of medical oxygen use in rural, mountainous and marginal areas far from cities.

In 1990, the U.S. introduced the oxygen produced by this technology, known as 93% oxygen and incorporation into the USP-XXII version of the United States Pharmacopeia. This oxygen is also included in the draft European Pharmacopoeia.

Characteristics of medical molecular sieve oxygen system

Working Principle of Medical Molecular Sieve Oxygen Concentrator

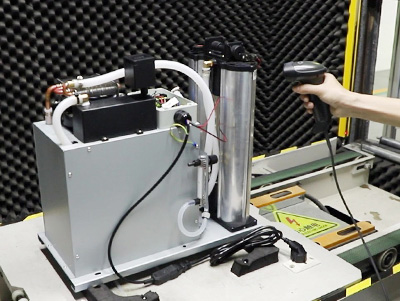

The medical molecular sieve oxygen system is mainly composed of air compressor, air filter, air storage tank, adsorption tower, oxygen storage tank, gas filter and other parts.The adsorption capacity of nitrogen increases when pressurized using a fractionated sieve at room temperature and low pressure. The decrease in the adsorption capacity of nitrogen at decompression results in pressurized adsorption. The rapid cycle of decompression and desorption allows the separation of oxygen and nitrogen in the air, allowing the separation of high concentrations of oxygen at 90% or more.

Advantages of medical molecular sieve oxygen system

Medical molecular sieve oxygen concentrators can be installed indoors, on the roof or in the basement.The ambient air around the machine room is relatively clean. No pollution sources, the air circulation in the machine room can meet the requirements of molecular sieve oxygen machine operation.This is an important reason for the popularity of molecular sieve oxygen systems in medical institutions in large cities.

The safety performance of molecular sieve oxygen concentrator is good when it operates in normal temperature and low pressure environment. A large amount of oxygen is stored in liquid oxygen tanks, and the consequences of a leak are very serious. There are also many safety hazards associated with cylinder oxygen supply.First of all, the cylinder filling pressure is high, the sun exposure temperature rise, encounter strong vibration or collision, there is a potential risk of explosion. Secondly, if the oxygen cylinder is not managed well, it is itself a direct or cross-infection vector. In addition, there is the problem that cylinder oxygen supply may be replaced by industrial oxygen.

The oxygen concentrator uses air as the raw material, consumes only electricity, and can produce oxygen continuously if the equipment operates normally. Both cylinder oxygen supply and liquid oxygen tank supply require regular replenishment from the oxygen manufacturer. Both types of oxygen supply run the risk of interruption of oxygen supply in areas where there is no oxygen source far or near.

The data in the table on the effectiveness of 93% oxygen shows that the main difference between 93% oxygen and medical oxygen is the inconsistency in concentration. The requirement of medical oxygen is more than 99.5%, and the oxygen of molecular sieve oxygen equipment is more than 90%. From the perspective of human respiratory physiology, the human body cannot metabolize without oxygen, and lack of oxygen is harmful to the human body and can be life-threatening in severe hypoxia. Clinical studies have shown that when the oxygen concentration is greater than 70%, continuous oxygen inhalation for 1d-2d can cause oxygen toxicity. For prolonged continuous isobaric oxygen therapy, adults should apply a gas mixture with an oxygen concentration of less than 60% and an oxygen partial pressure less than 60 kPa. The oxygen concentration should not exceed 60% and the partial pressure of oxygen should be less than 40 kPa for the treatment of newborn or breastfed infants.

In order to prevent oxygen toxicity due to inhalation of "pure oxygen" during resuscitation and treatment, the oxygen level of all ventilators and anesthesia machines is adjusted in the range of 21%`90%. As long as the oxygen content is ≥ 90%, it is sufficient for resuscitation and treatment of patients on respirators and anesthesia machines. Therefore, the 93% oxygen produced by the molecular sieve oxygen system is sufficient for general oxygen therapy and resuscitation and anesthesia treatment.A survey by the Royal College of Physicians of Canada's Department of Medicine reported that 48 of the 52 Canadian hospitals it surveyed used oxygen concentrators.

The safety of 93% oxygen has not been reported in national or international clinical reports of adverse reactions caused by 93% oxygen. A survey by the Royal College of Physicians of Canada's Department of Medicine reported that 48 of the 52 Canadian hospitals it surveyed used oxygen concentrators. The 1996 survey of clinical care included 30,642 surgical procedures, 9,415 intensive care cases, and 364,529 emergency cases, for a total of 106,819 h of oxygen concentrator use. The oxygen concentrator was available for use (52~58) percent of the 24-hour day. There were no reported medical complaints regarding oxygen concentrators during patient care. From 2003 to 2009, the National Adverse Drug Reaction Monitoring Center's medical device adverse event database did not receive any reports of suspicious medical device adverse events related to 93% oxygen.

The current application status of medical molecular sieve oxygen concentrators

Medical molecular sieve oxygen systems have been used in medical institutions in China for more than a decade, and controversies about whether this equipment is safe and can meet the needs of clinical use continue to arise.

In the process of testing and research, the use of oxygen concentrators in hospitals reflected more problems is not stable enough oxygen concentration. The reason for this problem is not only the individual use and improper maintenance. The main reason is that the oxygen concentrator purchased by the hospital cannot produce enough gas for clinical use. This problem is even more pronounced during peak oxygen usage times. Another problem is that the oxygen concentration meters used in hospitals are not accurate. Although molecular sieve plants are equipped with online oxygen concentration detectors, these detectors vary in size and accuracy. The readings on the oxygen concentration analyzer are inaccurate compared to the final test results. These concentrators are only calibrated by the manufacturer at the factory and are not regularly measured during use.

From the perspective of each hospital, there is no uniform standard for the management of molecular sieve equipment. There is no uniform standard for the management of molecular sieve equipment in hospitals, and the manufacturers are not consistent in their training of equipment maintenance and management personnel.

Summary

As a facility that is maintained and supervised by the hospital itself, it is necessary for the hospital to ensure the quality of the oxygen it produces and the safety of clinical oxygen use.

As a hospital oxygen supply system, it is necessary to ensure that the oxygen source is adequate. There is no interruption of oxygen supply or insufficient oxygen supply. The molecular sieve system selected as the oxygen supply system should be configured with the corresponding gas production capacity according to the daily oxygen consumption of the hospital and the oxygen consumption at the peak of oxygen consumption. The hospital must have the appropriate secondary and reserve oxygen supply system and the corresponding gas storage capacity must be specified.

Online oxygen concentration analyzers are an important tool for hospital maintenance personnel to monitor the proper operation of molecular sieve oxygen concentrators. Relevant requirements are needed to standardize the use. At the same time, regular measurement of the oxygen concentration analyzer is an important guarantee for reliable monitoring results.

The existing operating procedures of the hospital mainly guarantee the effectiveness of oxygen, but there is no corresponding testing means for the items that affect the safety of oxygen. These requirements and testing methods are worthwhile for hospital facility management. In addition, it is necessary for the testing organization to conduct periodic testing of the hospital's oxygen quality.

The stable operation of molecular sieve equipment requires professional personnel to maintain the equipment and to be able to solve the problems that arise in a timely manner. Professional training should be provided to maintenance personnel. In addition, clinicians should be informed that the oxygen source used should be promptly recorded and reported in case of clinical problems to provide more detailed clinical information for the application of molecular sieve equipment.

Although it is well documented that medical molecular sieve systems cost less per unit volume of gas produced, molecular sieve equipment can operate for more than a decade with good maintenance and is more economical in the long run than other forms of oxygen supply. However, when medical institutions introduce medical molecular sieve oxygen systems, they should consider other factors such as energy consumption and maintenance costs, and should not invest blindly.

Keywords: oxygen concentrator

Originally published 02 Dec 2022, updated 02 Dec 2022.